Our team is often asked about engine management systems. As a crossover to avionics and maintenance, we are contending with numerous variants: engines, aircraft manufacturers, avionics manufacturers.

Mixing the tech of avionics with engine performance and maintenance, an engine monitor can ensure longevity -- and safety.

As with all projects, engine management is very customized. Our buyer’s guide will help you choose which system is ideal for your airplane.

Primary or Secondary?

Engine monitors, or engine management or engine information systems (EIS), are divided into subsets of Primary and Secondary systems, also known as Certified Advisory and Secondary Advisory. What this essentially means is Primary will replace your airplane’s existing engine instruments, thus becoming a single-point resource for a custom engine (and in most cases, fuel management) profile. Secondary systems will offer at-a-glance engine data for a selectable set of parameters, but you will retain the engine instruments (thus, the terms “certified” and “secondary” advisory).

What's the Best Choice for Your Aircraft?

Aircraft owners often ask if they should consider a primary or secondary system. Let’s take a look at a real-life product comparison. The aircraft we’re shopping for has factory original engine gauges, and is 1975 Cessna 182P with a Continental O-470. The owner isn’t sure if he wants a primary or a secondary system, but he has narrowed his search to the EDM830 or the GI-275. He was attracted to the features and compact size of both products.

He also mentioned that this was an airplane he planned to own long-term, and that he had an engine nearing TBO. He does not plan to make any kind of engine swap or mods at that time, which is important to consider before planning an engine monitor upgrade; these instruments are programmed for the engine, so this could negate some or all of the progress being made now, and potentially require future probes, sensors, downtime and labor.

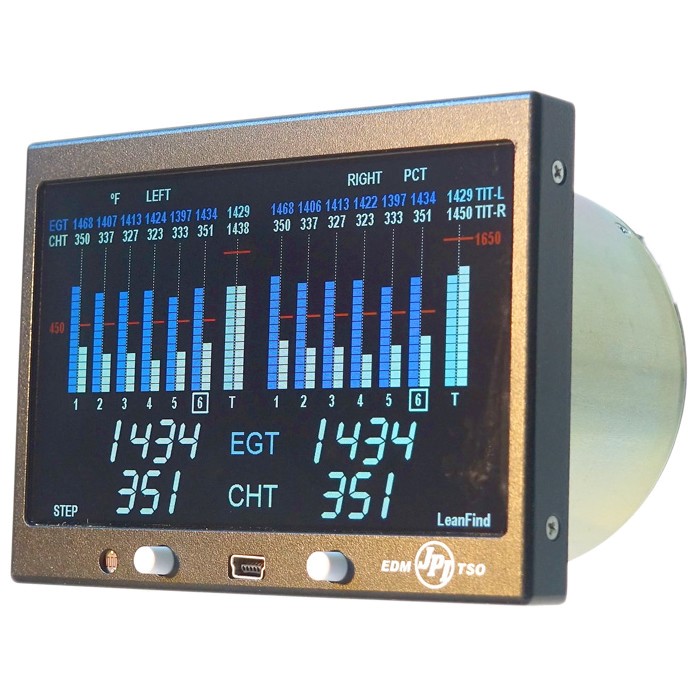

A product like JP Instruments' EDM830 is secondary, meaning you would retain the OEM and factory instruments and gauges, but install a single-point resource for more precise engine indication.

Benefits:

- Minimal panel work needed, if any.

- Ease of installation.

- At-a-glance information of engine functions, which are customizable with various functions and display formats.

- The 830 displays EGT's, CHT's, TIT and/or Oil Temp (digital and bar graph display).

- Other temperatures & functions displayed digitally only. Engine analysis performed automatically with Pilot Programmable Over-Temp Limits, a Differential Limit and a Shock-Cooling Limit. Range for Bars and Scan Rate are also Pilot Programmable. Proprietary Peak Detect for ROP and LOP eliminates false peak readings.

- Displays Temperature Below Peak EGT for accurate Leaning. Fuel/Air Mixture Profiling.

The other contender, the GI-275 EIS, is a primary system, meaning we would remove existing gauges and instruments and replace them with a single unit.

Each engine will require one GI-275, plus the GEA24 (the brains) and then the appropriate sensor kit. The GI 275 is capable of interfacing with single-engine and multi-engine normally aspirated or turbocharged aircraft with select powerplants, including Lycoming and Continental 4/6-cylinder engines (more available options for the Experimental market). When the GI 275 replaces mechanical gauges and is configured as primary for engine information, the GI 275 can display RPM, manifold pressure, oil pressure and temperature, cylinder head temperature (CHT), exhaust gas temperature (EGT), turbine inlet temperature (TIT), fuel flow, fuel quantity, fuel pressure, volts and amps. Lean assist functionality is also available so pilots can choose to operate rich of peak or lean of peak. It also features exceedance alerting, with configurable caution and warning alerts per the Pilots Operating Handbook (POH). Pilot programmable settings are also available, such as advisory alerts like “high oil temp” or “high CHT”. Engine data can be shared wirelessly with the Garmin Pilot app on Apple mobile devices and can also be viewed on the flyGarmin website for post-flight analysis.

Benefits:

- Robust, all-in-one engine management system, including fuel management

- Ease-of-use, operation and reporting functions

- Asethetics: fits into a standard round instrument cut-out

- Requires less panel work than large format displays

Installing the CGR 30C in a 1979 Piper Dakota

This was a light upgrade in which we replaced an aging stack consisting of a KMA20 analog audio panel, a pair of KX-170B nav/coms and a DME, and a KT-76 transponder. The center stack upgrade included the Garmin GMA345 Bluetooth® Audio Panel, GNC255A nav/com, GTR225 com, and GNX375 GPS Navigator and ADS-B Out/In Transponder. A Garmin GI 275 CDI Course Deviation Indicator finalized the upgrade to the nav equipment.

The customer also wanted a tach replacement, in which after considering a direct replacement, chose the Electronics International CGR-30C to enhance the functionality of his panel. The CGR-30C can replace up to 16 Primary Instruments, which means you can remove an entire engine cluster with a single 3-1/8” electronic replacement. In addition to replacing a faulty tachometer, the owner of this Dakota consolidated engine management and was able to obtain RPM, manifold pressure, fuel flow, fuel pressure and measurement, and oil pressure and temperature parameters within one instrument. This was also done with minimal panel work and cost.

Primary Engine Management

The Garmin G500 TXi pictured includes the Engine Indication System interface module and sensors, serving as an all-in-one primary display. This is in a twin-engine Piper Aztec; note the incredible amount of information available in a single-screen format.

Other Considerations

With most primary EIS systems, the instrument panel, or a portion of it, will need to be refurbished/modified. We can also fabricate blank-outs or small plates which are then painted to match the panel. Since the cost of a new panel can be substantial, factoring in aesthetics is not inconsequential to the budget.

The timeline for installation will be affected by these factors as well.

Our management team performs a final inspection to make sure that all equipment installed tests to manufacturer’s specifications and meets the criteria set forth by Sarasota Avionics, the FAA and the Customer. Sarasota Avionics has the experience necessary to make sure your installation meets our stringent quality standards. We ensure that our avionics installations provide trouble-free, high-quality performance that deliver the standards the avionics manufacturer promised year after year.

These details matter when focusing on the health of your engine and aircraft overall. Labor is to be expected at or near the same, product-to-product, when compared congruently to other primary or secondary systems.

Fuel Management

Fuel senders are pivotal components to the airplane of course, but also in furnishing vital information to pilots about the fuel levels in the tanks. Older aircraft fuel senders (along with their gauges) suffer from issues of unreliability and inaccuracy. The two legacy methods to measure fuel in aircraft are Capacitive and Resistive.

New Tech in Fuel Senders

Magnetic fuel senders offer numerous advantages over legacy senders: chiefly, in accurately measuring fuel quantity and ensuring safe and efficient operation of fuel tanks. Simple in design but providing high accuracy and immunity to common issues, they’re a great solution for a variety of fuel measurement applications. Furthermore, their non-electrical contact measurement method and lack of electronic components in the fuel tank make them intrinsically safe, reducing the risk of hazards.

The non-electrical contact measurement method allows them to be immune to changes in fuel motion, water in the fuel, and the presence of corrosion. This unique feature ensures that the fuel level readings remain consistent and accurate. Magnetic fuel senders have the highest accuracy available for fuel quantity measurement, exceeding 0.75%, with no measurable error or hysteresis in TSO testing. Thus, the senders’ capability to dampen fuel motion and resist the effects of fuel oscillation reinforces their reliability even in turbulent flight conditions.

Recap

Which choice is right for you?

- Budget

- Engine life

- Establish the parameters or factors for engine management that matter most to you as an owner, operator and pilot alike.

- Determine what reporting capabilities you would like to have. The various avionics manufacturers offer different platforms for reporting. Some can offer cross-platform interface capabilities.

Want to learn more?

Our avionics consultants can walk you through the many options and determine what product(s) will work best for your airplane. Have a panel photo ready and contact our team to discuss the best solution to fit your budget.

About Our Company

Our staff consists of people who got into this business because they love aviation. We are always here to answer any questions you may have about all of the current avionics options, and to help you find the right solution for your aircraft.

Besides offering the best prices and customer service in the industry, Sarasota Avionics & Maintenance sets itself apart from the competition by offering multiple locations throughout Florida. Providing both avionics and maintenance services all under one roof makes scheduling easier with far less downtime.